Storing, Transportation and Delivery of Explosives at Site

- Drilling and Blasting Services.

- Drilling and Blasting Design.

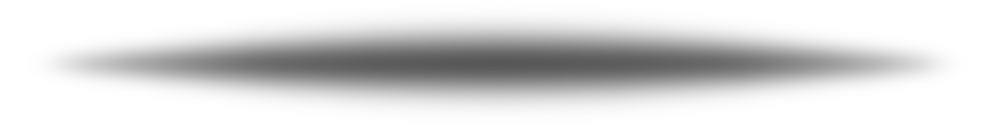

- Surface and Underground Applications with Explosives Charging Trucks.

- Specific Blasting Applications.

- Controlled Blasting Applications.

- Blasting Vibration Control Services.

- Storing, Transportation and Delivery of Explosives at Site.

- Project Designing, Installation, Testing & Commissioning, Start-up of Emulsion Explosives Plants, Non-Electric Detonator Assembly Plants and ANFO Plants.

- Installation and Start-up of Surface/Underground Emulsion Charging Units (MMU/Unibody Trucks) and ANFO Charging Units (ANFO Trucks).

- Drilling and Blasting Services.

- Drilling and Blasting Design.

- Surface and Underground Applications with Explosives Charging Trucks.

- Specific Blasting Applications.

- Controlled Blasting Applications.

- Blasting Vibration Control Services.

- Storing, Transportation and Delivery of Explosives at Site.

- Project Designing, Installation, Testing & Commissioning, Start-up of Emulsion Explosives Plants, Non-Electric Detonator Assembly Plants and ANFO Plants.

- Installation and Start-up of Surface/Underground Emulsion Charging Units (MMU/Unibody Trucks) and ANFO Charging Units (ANFO Trucks).

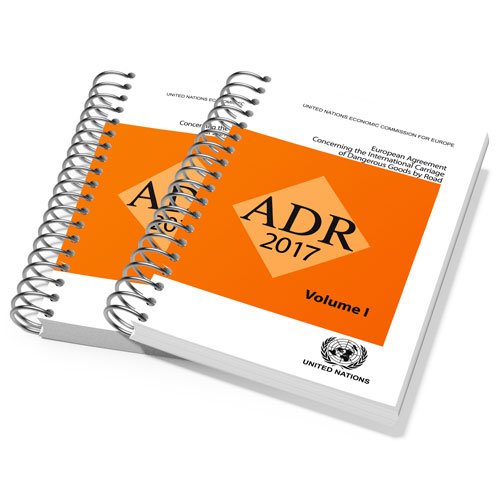

GEO-NITRO provides a complete Drilling & Blasting design (Pattern Design) and site consulting services to customers with its specialist drilling & blasting engineers. The world’s most advanced drilling & blasting softwares which are Shot Plus5, Shot Plus-T, Shot Plus-UG and Powersieve, enables various opportunities to site engineers. GEO-NITRO provides project designing, installation, testing & commissioning, start-up services of commercial explosives manufacturing plants by its specialist project development & technology team. Additionally, the installation & start-up of surface emulsion charging units (MMU/Unibody Truck), surface ANFO charging units (ANFO Trucks) and underground charging equipments are being provided.

Specific Blasting Applications

- Drilling and Blasting Services.

- Drilling and Blasting Design.

- Surface and Underground Applications with Explosives Charging Trucks.

- Specific Blasting Applications.

- Controlled Blasting Applications.

- Blasting Vibration Control Services.

- Storing, Transportation and Delivery of Explosives at Site.

- Project Designing, Installation, Testing & Commissioning, Start-up of Emulsion Explosives Plants, Non-Electric Detonator Assembly Plants and ANFO Plants.

- Installation and Start-up of Surface/Underground Emulsion Charging Units (MMU/Unibody Trucks) and ANFO Charging Units (ANFO Trucks).

- Drilling and Blasting Services.

- Drilling and Blasting Design.

- Surface and Underground Applications with Explosives Charging Trucks.

- Specific Blasting Applications.

- Controlled Blasting Applications.

- Blasting Vibration Control Services.

- Storing, Transportation and Delivery of Explosives at Site.

- Project Designing, Installation, Testing & Commissioning, Start-up of Emulsion Explosives Plants, Non-Electric Detonator Assembly Plants and ANFO Plants.

- Installation and Start-up of Surface/Underground Emulsion Charging Units (MMU/Unibody Trucks) and ANFO Charging Units (ANFO Trucks).

GEO-NITRO provides a complete Drilling & Blasting design (Pattern Design) and site consulting services to customers with its specialist drilling & blasting engineers. The world’s most advanced drilling & blasting softwares which are Shot Plus5, Shot Plus-T, Shot Plus-UG and Powersieve, enables various opportunities to site engineers. GEO-NITRO provides project designing, installation, testing & commissioning, start-up services of commercial explosives manufacturing plants by its specialist project development & technology team. Additionally, the installation & start-up of surface emulsion charging units (MMU/Unibody Truck), surface ANFO charging units (ANFO Trucks) and underground charging equipments are being provided.

Geo-Nitro serves customers at following ENGINEERING and SERVICE fields

- Drilling and Blasting Services.

- Drilling and Blasting Design.

- Surface and Underground Applications with Explosives Charging Trucks.

- Specific Blasting Applications.

- Controlled Blasting Applications.

- Blasting Vibration Control Services.

- Storing, Transportation and Delivery of Explosives at Site.

- Project Designing, Installation, Testing & Commissioning, Start-up of Emulsion Explosives Plants, Non-Electric Detonator Assembly Plants and ANFO Plants.

- Installation and Start-up of Surface/Underground Emulsion Charging Units (MMU/Unibody Trucks) and ANFO Charging Units (ANFO Trucks).

- Drilling and Blasting Services.

- Drilling and Blasting Design.

- Surface and Underground Applications with Explosives Charging Trucks.

- Specific Blasting Applications.

- Controlled Blasting Applications.

- Blasting Vibration Control Services.

- Storing, Transportation and Delivery of Explosives at Site.

- Project Designing, Installation, Testing & Commissioning, Start-up of Emulsion Explosives Plants, Non-Electric Detonator Assembly Plants and ANFO Plants.

- Installation and Start-up of Surface/Underground Emulsion Charging Units (MMU/Unibody Trucks) and ANFO Charging Units (ANFO Trucks).

GEO-NITRO provides a complete Drilling & Blasting design (Pattern Design) and site consulting services to customers with its specialist drilling & blasting engineers. The world’s most advanced drilling & blasting softwares which are Shot Plus5, Shot Plus-T, Shot Plus-UG and Powersieve, enables various opportunities to site engineers. GEO-NITRO provides project designing, installation, testing & commissioning, start-up services of commercial explosives manufacturing plants by its specialist project development & technology team. Additionally, the installation & start-up of surface emulsion charging units (MMU/Unibody Truck), surface ANFO charging units (ANFO Trucks) and underground charging equipments are being provided.

Drilling and Blasting Design

- Drilling and Blasting Services.

- Drilling and Blasting Design.

- Surface and Underground Applications with Explosives Charging Trucks.

- Specific Blasting Applications.

- Controlled Blasting Applications.

- Blasting Vibration Control Services.

- Storing, Transportation and Delivery of Explosives at Site.

- Project Designing, Installation, Testing & Commissioning, Start-up of Emulsion Explosives Plants, Non-Electric Detonator Assembly Plants and ANFO Plants.

- Installation and Start-up of Surface/Underground Emulsion Charging Units (MMU/Unibody Trucks) and ANFO Charging Units (ANFO Trucks).

- Drilling and Blasting Services.

- Drilling and Blasting Design.

- Surface and Underground Applications with Explosives Charging Trucks.

- Specific Blasting Applications.

- Controlled Blasting Applications.

- Blasting Vibration Control Services.

- Storing, Transportation and Delivery of Explosives at Site.

- Project Designing, Installation, Testing & Commissioning, Start-up of Emulsion Explosives Plants, Non-Electric Detonator Assembly Plants and ANFO Plants.

- Installation and Start-up of Surface/Underground Emulsion Charging Units (MMU/Unibody Trucks) and ANFO Charging Units (ANFO Trucks).

GEO-NITRO provides a complete Drilling & Blasting design (Pattern Design) and site consulting services to customers with its specialist drilling & blasting engineers. The world’s most advanced drilling & blasting softwares which are Shot Plus5, Shot Plus-T, Shot Plus-UG and Powersieve, enables various opportunities to site engineers. GEO-NITRO provides project designing, installation, testing & commissioning, start-up services of commercial explosives manufacturing plants by its specialist project development & technology team. Additionally, the installation & start-up of surface emulsion charging units (MMU/Unibody Truck), surface ANFO charging units (ANFO Trucks) and underground charging equipments are being provided.

Warning: count(): Parameter must be an array or an object that implements Countable in /home/geonitro/public_html/modules/mod_eshop_product/helper.php on line 43

Warning: count(): Parameter must be an array or an object that implements Countable in /home/geonitro/public_html/modules/mod_eshop_product/helper.php on line 49